Expert Insights: The Future of Partial Discharge Detection Technologies

Understanding Partial Discharge Detection

Partial discharge (PD) detection is a crucial aspect of maintaining the health and functionality of electrical systems. It involves identifying and analyzing partial discharges, which are tiny electrical sparks that occur when there is a breakdown in the insulation of electrical equipment. These discharges, although minor, can lead to significant equipment damage if left unchecked.

Traditionally, PD detection has relied on methods such as ultrasonic sensors and electrical sensors to capture and interpret these signals. However, as technology advances, so do the methods of detecting and analyzing PD, leading to more efficient and accurate systems.

Technological Advancements in PD Detection

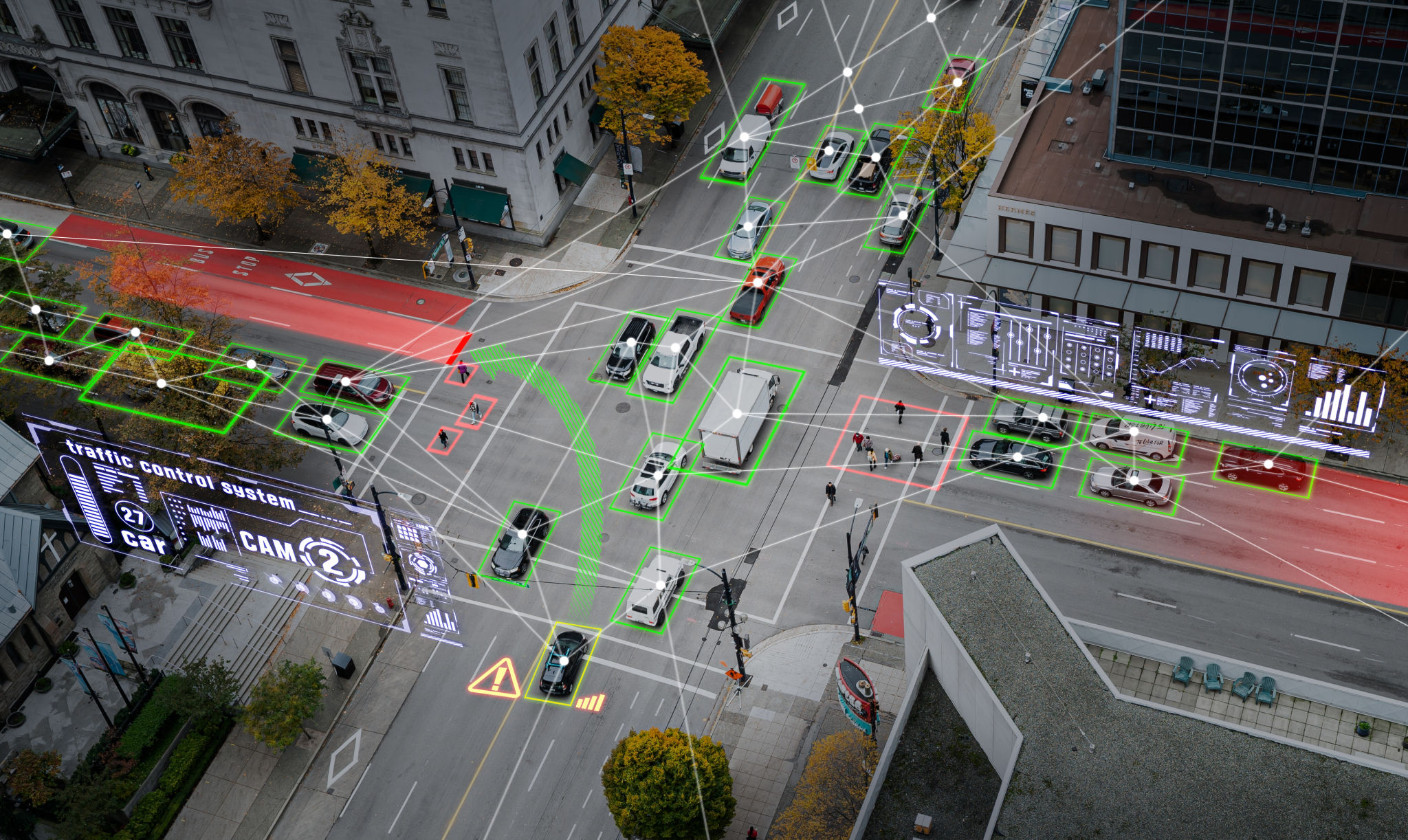

The future of partial discharge detection lies heavily in the integration of advanced technologies. **Artificial intelligence (AI)** and machine learning are playing significant roles in transforming how PD is detected. By utilizing these technologies, systems can now learn from a vast array of data, enabling more accurate predictions and analysis.

Additionally, the development of **smart sensors** is proving to be a game-changer. These sensors are not only more sensitive but also capable of operating in harsh environments, providing real-time data that is crucial for maintaining system integrity.

AI and Machine Learning Applications

Incorporating AI in PD detection allows for the automation of data analysis, reducing the need for human intervention and minimizing errors. Machine learning algorithms can process large volumes of data to identify patterns and predict potential failures before they occur. This proactive approach significantly improves the reliability and safety of electrical systems.

The Role of IoT in PD Detection

The **Internet of Things (IoT)** is another pivotal technology enhancing PD detection capabilities. IoT devices facilitate continuous monitoring by connecting various sensors and systems over the internet, enabling seamless data collection and sharing. This connectivity allows for real-time monitoring and swift response to potential issues.

Furthermore, IoT integration can lead to the development of predictive maintenance strategies. By analyzing data trends, businesses can anticipate equipment failures and schedule maintenance before a critical breakdown occurs, ultimately saving time and resources.

Benefits of Predictive Maintenance

Predictive maintenance strategies offer numerous benefits, including reduced downtime, cost savings on repairs, and extended equipment lifespan. By addressing issues before they escalate, organizations can enhance operational efficiency and ensure the safety of their infrastructure.

Challenges and Considerations

While the future of PD detection technologies looks promising, there are challenges to consider. **Data security** is a primary concern as more systems become interconnected. Ensuring that sensitive information is protected from cyber threats is crucial.

Moreover, the initial investment in advanced PD detection technologies can be substantial. However, the long-term benefits often outweigh these initial costs, making it a worthwhile investment for many businesses.

The Path Forward

As technology continues to evolve, so too will the methods for detecting partial discharges. Emphasizing research and development in this field will be essential for creating even more sophisticated tools and strategies. Collaboration between technology providers and industry stakeholders will also play a critical role in driving innovation forward.

Conclusion

The future of partial discharge detection technologies promises enhanced accuracy, reliability, and efficiency. By leveraging advancements in AI, IoT, and smart sensors, industries can look forward to improved safety and performance in their electrical systems. As we move forward, embracing these technologies will be key to staying ahead in an increasingly competitive landscape.